- This topic is empty.

-

AuthorPosts

-

2025-12-05 at 6:34 pm #82471

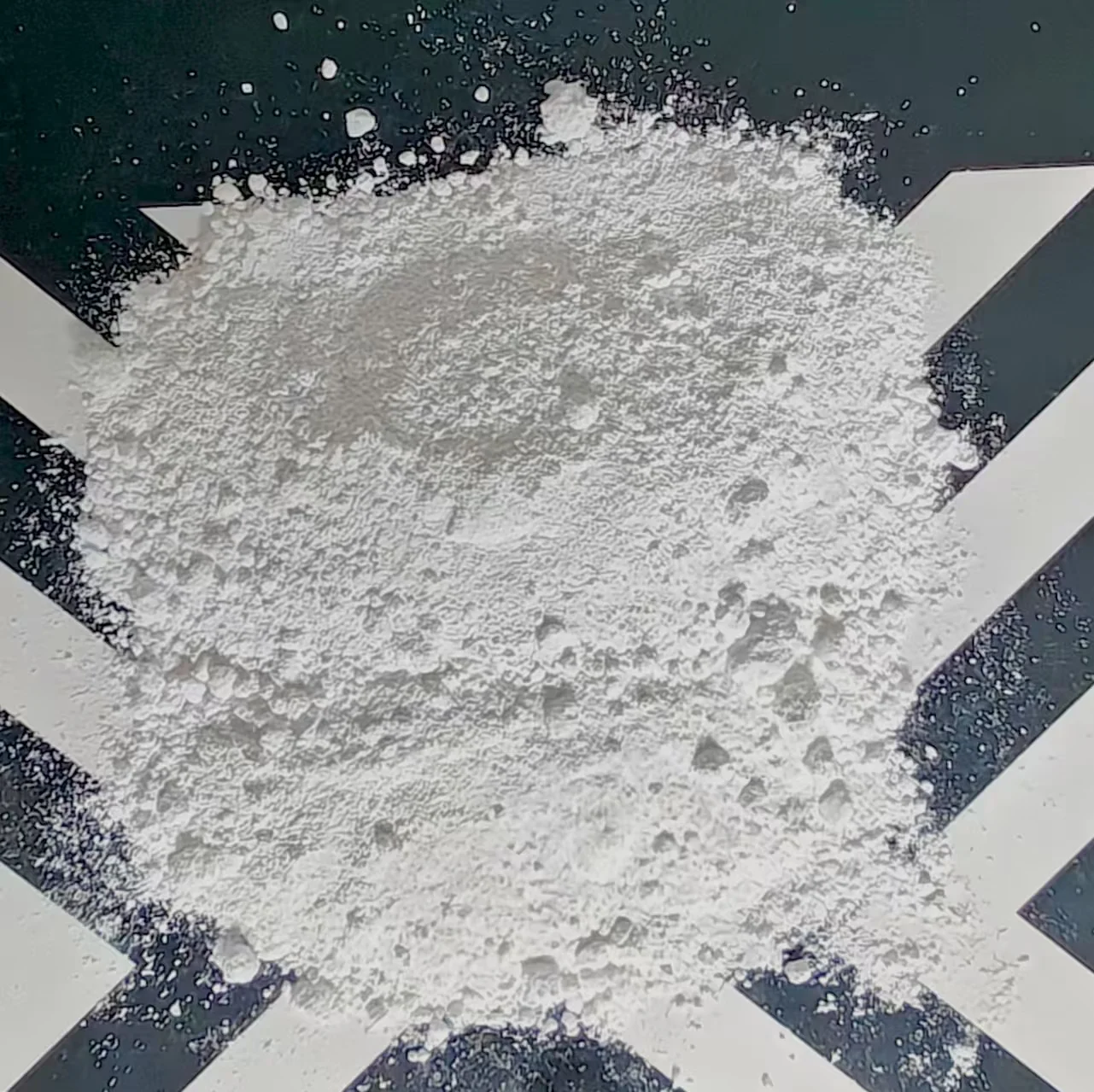

Titanium dioxide (TiO₂) remains one of the most essential functional materials in the coatings industry, offering brightness, opacity, UV resistance, and long-term durability. Among its various forms, TiO2 rutile powder is recognized for its superior refractive index, weather resistance, and dispersion behavior, making it a preferred choice for premium coating formulations. In this blog post, ALATAI TIO2, as high quality powder coating raw materials manufacturing factory, will share information on TiO2 rutile powder for coatings in industrial applications.

Understanding TiO2 Rutile Powder and Its Role in Coatings

Rutile is the most stable crystalline form of titanium dioxide, providing excellent optical and physical properties essential for high-performance coatings. TiO2 rutile powder for coatings is engineered through advanced chloride or sulfate processes, producing fine, highly pure particles with controlled size distribution.

Compared with anatase TiO₂, rutile offers higher opacity and stronger UV shielding. Its dense crystal structure enhances durability, making rutile powder ideal for architectural coatings, industrial coatings, marine coatings, automobile finishes, and protective layers requiring long-term stability.

Key Properties of Rutile TiO2 Powder for Industrial Coating Use

The success of rutile TiO₂ powder for coatings in demanding environments stems from several well-defined material properties:

1. Exceptional Refractive Index and Hiding Power

Rutile TiO₂ has a refractive index of approximately 2.7, significantly higher than most common pigments. This feature leads to outstanding opacity, reducing coating thickness and improving coverage. Manufacturers can use less pigment while achieving better color performance and hiding effects.

2. Strong UV Absorption and Protection

Due to its unique crystal lattice and electron band structure, rutile TiO₂ efficiently absorbs and scatters UV radiation. In coatings, this prevents degradation of the polymer matrix, slowing yellowing, chalking, and surface aging. As a result, UV-resistant architectural and automotive coatings rely heavily on rutile-grade titanium dioxide.

3. High Weatherability and Corrosion Resistance

Rutile particles remain stable under sunlight, humidity, and chemical exposure. This makes TiO₂ rutile powder for coatings an excellent choice for exterior applications such as building facades, bridges, marine vessels, and outdoor machinery. When combined with inorganic surface treatments like alumina or silica, rutile powder further enhances weather resistance.

4. Controlled Particle Size for Smooth Film Formation

Modern production techniques ensure that rutile particles exhibit a narrow size distribution, typically around 200–300 nm. This uniformity promotes superior dispersion in resin systems, resulting in a smooth, consistent coating film with minimal agglomeration.

Advantages of TiO2 Rutile Powder for Coating Formulations

The incorporation of tio2 rutile powder for coatings significantly elevates the overall quality and performance of coating materials. Several advantages are particularly notable:

High Opacity with Lower Pigment Volume

Because rutile TiO₂ provides excellent hiding power, coating formulators can reduce pigment loading while still maintaining effective coverage. This increases cost efficiency without compromising color intensity or brightness.

Improved Film Durability

Rutile TiO₂ enhances mechanical stability, reducing the risk of microcracking and coating failure. Products experience extended service life even in aggressive industrial environments.

Enhanced Color Retention

Rutile TiO₂ minimizes color fading by protecting the binder from UV radiation. High-performance paints, automotive coatings, and marine coatings rely on this capability to maintain visual appeal over time.

Superior Gloss Control

With appropriate surface treatment, rutile powder contributes to glossy, semi-gloss, or matte finishes depending on formulation requirements. It supports both decorative and functional coating designs.

TiO2 Rutile Grade Variations Used in Coating Applications

Manufacturers produce different grades of TiO₂ rutile powder for coatings, each tailored to specific applications. Common categories include:

Surface-Treated Rutile TiO₂

To improve compatibility with organic binders, rutile particles are often coated with compounds such as silicon dioxide, aluminum oxide, or zirconium compounds. These surface treatments enhance dispersion, hydrophobicity, and resistance to photochemical reactions.

Chloride-Process Rutile TiO₂

Chloride-processed titanium dioxide offers high purity, low impurity levels, and brilliant whiteness. It is preferred for automotive coatings, powder coatings, and advanced industrial coatings requiring superior brightness and durability.

Sulfate-Process Rutile TiO₂

Sulfate-process grades are cost-effective and widely used in decorative architectural paints and general-purpose coatings. They maintain excellent opacity and color performance while offering stable economic benefits.

Nano-Rutile TiO₂ for Functional Coatings

Nanostructured rutile TiO₂ is used in self-cleaning coatings, photocatalytic films, and high-UV-blocking surface layers. Its ability to generate reactive oxygen species under UV exposure enables antimicrobial and air-purifying functionalities.

Applications of Rutile Titanium Dioxide Across Coating Segments

Architectural Coatings

Exterior and interior paints benefit from rutile TiO₂’s opacity, weather resistance, and color stability. It helps create uniform coatings that withstand rain, sunlight, and mechanical abrasion. Premium wall paints, façade coatings, and roof coatings commonly feature rutile-grade powder.

Industrial Protective Coatings

For industrial environments, coatings must resist abrasion, chemical exposure, and UV degradation. Rutile TiO₂ powder for coatings enhances film strength, reduces chalking, and maintains long-term gloss—critical for protective coatings applied to infrastructure, pipelines, and heavy machinery.

Automotive Coatings

Automotive paints require high brightness, scratch resistance, and weatherability. Chloride-process rutile TiO₂ ensures vivid color tones and a long-lasting appearance. It is used in basecoats, topcoats, and refinishing products.

Marine and Anti-Corrosion Coatings

Coatings used on ships, offshore platforms, and port equipment face extreme environmental conditions. Rutile TiO₂ improves hydrophobicity and corrosion resistance, ensuring durable performance in saltwater and humid environments.

Powder Coatings

Rutile TiO₂ enhances powder coating flow characteristics and UV stability. This helps create smooth, durable finishes for home appliances, metal furniture, building materials, and industrial equipment.

How to Select Suitable TiO2 Rutile Powder for Coating Systems

Choosing the right rutile TiO₂ powder for coatings involves evaluating several formulation requirements:

Evaluate Surface Treatment

Different applications may require hydrophilic or hydrophobic surfaces, improved gloss, or enhanced UV resistance. Surface treatment type significantly impacts the final coating performance.

Consider Dispersibility

Highly dispersible grades reduce processing time, minimize agglomeration, and ensure uniform color. This is critical for water-based coatings and high-viscosity resin systems.

Assess Purity and Whiteness

Automotive and decorative coatings demand high whiteness levels for accurate color matching. Purity impacts optical performance and film aesthetics.

Check Compatibility with Binder Systems

Some coatings rely on acrylics, polyurethanes, epoxies, or alkyd resins. Choosing a TiO₂ grade compatible with the binder ensures optimal film formation and stability.

Future Directions of Using Rutile TiO2 in Coating Technologies

As coating technologies evolve, TiO₂ rutile powder for coatings continues to play a central role in innovation. Key future trends include:

-

Low-VOC and eco-friendly coatings requiring high-efficiency pigments to reduce material consumption

-

Smart coatings that integrate UV-responsive, self-cleaning, or antimicrobial properties

-

Advanced dispersion technologies enabling smoother films with less energy input

-

Durability-focused formulations for long-term climate resilience and sustainability

Rutile TiO₂ is expected to remain a core material in next-generation coating solutions, supporting energy-efficient buildings, high-performance vehicles, and long-lasting industrial equipment.

Conclusion

TiO2 rutile powder for coatings is an essential material for modern coating applications, offering unparalleled opacity, UV protection, whiteness, and durability. With specialized grades tailored to different formulations, rutile TiO₂ supports industrial coatings, automotive finishes, architectural paints, powder coatings, and functional surface layers. As global markets demand higher efficiency and longer service life, rutile titanium dioxide will continue to underpin technological progress in coating performance and sustainability.

If you would like this article rewritten with a different keyword combination, tone, or structure, I can refine it further.

http://www.titanmastech.com

ALATAI TIO2 -

-

AuthorPosts

- You must be logged in to reply to this topic.