- This topic is empty.

-

AuthorPosts

-

2025-03-12 at 11:10 am #80532

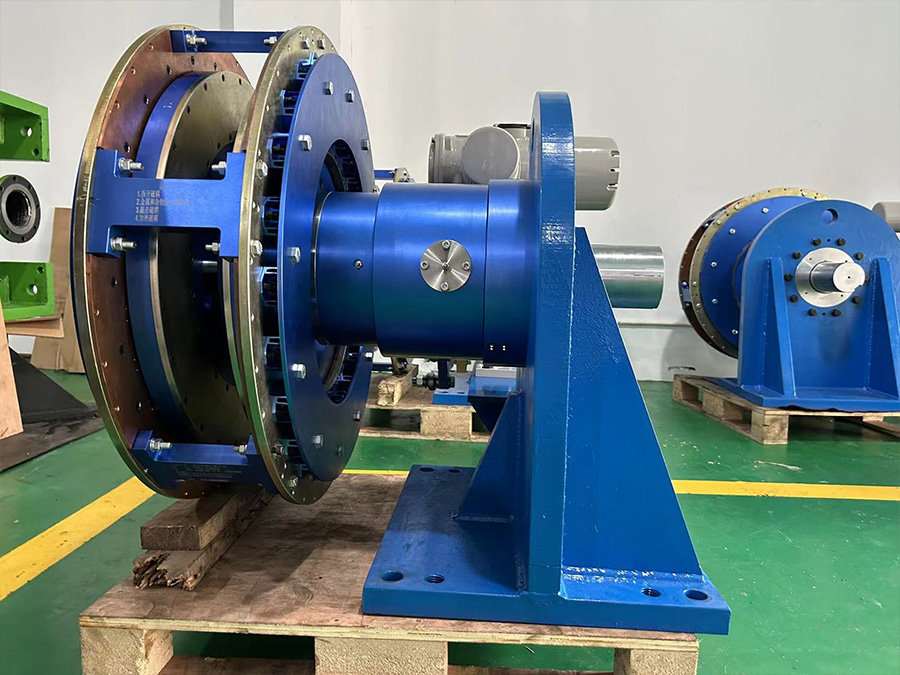

Disc type speed control magnetic couplers are a modern advancement in non-contact power transmission systems. These couplers utilize the principles of magnetic induction to transfer torque between the driving and driven components without any physical contact. The system consists of two main parts: a magnetic rotor and a conductive rotor. The magnetic rotor, typically made of high-performance permanent magnets, generates a magnetic field that interacts with the conductive rotor to produce a torque. By adjusting the air gap between these two rotors, the speed and torque can be precisely controlled.

Enhanced Efficiency and Dynamic Performance

SHANGHAI GAOLV E&M TECHNOLOGY CO.,LTD. is a professional disc type speed control magnetic coupler manufacturer.

One of the most significant advantages of disc type speed control magnetic couplers is their superior efficiency compared to traditional eddy current couplers. Eddy current couplers, while widely used, suffer from inherent limitations such as high eddy current losses, lower torque capacity, and poor dynamic performance. These losses result in wasted energy and reduced overall system efficiency.

In contrast, disc type magnetic couplers are designed to minimize energy losses. The optimized magnetic field configuration ensures that the magnetic flux is efficiently utilized, resulting in higher torque output with less energy input. This efficiency improvement translates to significant cost savings over the operational lifetime of the equipment, especially in high-power applications.

Dynamic Tracking and Control

Another key advantage of disc type speed control magnetic couplers is their enhanced dynamic performance. These couplers can quickly respond to changes in load conditions, providing precise speed and torque control. This is particularly important in applications where variable speed control is required, such as in pumps, fans, and conveyor systems. The ability to dynamically adjust the speed and torque allows for better process control, energy optimization, and reduced wear on mechanical components.

Reduced Maintenance and Increased Reliability

The non-contact nature of disc type speed control magnetic couplers means that there is no mechanical wear between the driving and driven components. This eliminates the need for frequent maintenance tasks such as lubrication and alignment adjustments, which are common with traditional mechanical couplers. Additionally, the absence of physical contact reduces the risk of mechanical failures, leading to increased system reliability and uptime.

Environmental and Safety Benefits

Disc type speed control magnetic couplers also offer environmental and safety benefits. Their high efficiency reduces energy consumption, contributing to lower carbon emissions and a smaller environmental footprint. Moreover, the non-contact operation minimizes the risk of fluid leaks and contamination, making them ideal for applications in sensitive environments such as food processing, pharmaceuticals, and chemical industries.

Market Comparison: Disc Type vs. Traditional Eddy Current Couplers

When comparing disc type speed control magnetic couplers to traditional eddy current couplers, the differences are stark. Traditional eddy current couplers are known for their high energy losses due to eddy currents, which result in lower torque capacity and reduced efficiency. These couplers also have limited dynamic performance, making them less suitable for applications requiring precise speed control.

On the other hand, disc type magnetic couplers are engineered to overcome these limitations. They offer higher torque capacity, better dynamic response, and significantly reduced energy losses. The optimized magnetic field design ensures that the energy is efficiently transferred, resulting in higher overall system efficiency. This makes disc type couplers a more cost-effective and environmentally friendly solution in the long run.

http://www.magicmag-tech.com

SHANGHAI GAOLV E&M Technology Co.,Ltd. -

AuthorPosts

- You must be logged in to reply to this topic.