- This topic is empty.

-

AuthorPosts

-

2025-09-22 at 1:42 pm #81982

1. Introduction: Fork Machining Services in the Global Era

In today's fast-paced global manufacturing landscape, precision and efficiency are not optional—they're essential. Advanced fork machining services are now playing a crucial role in supporting industries such as automotive, logistics, construction machinery, and agriculture. As global competition intensifies, manufacturers increasingly seek reliable partners who can deliver high-quality, tailor-made components like forklift forks and frames at scale and speed. This is where Hengli, a trusted leader in metal processing solutions, excels.

With more than two decades of industry experience, Hengli has developed a comprehensive fork machining service that integrates cutting-edge technology, experienced talent, and customer-focused processes to serve the evolving needs of global manufacturers.

2. Who Needs Advanced Fork Machining?

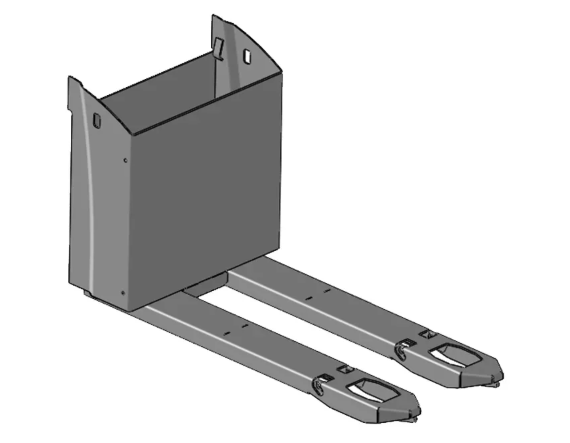

Fork machining is essential for any industry that uses forklifts or similar heavy-duty lifting equipment. This includes logistics centers, warehouses, construction sites, ports, and agricultural storage facilities. The reliability of forklift components such as forks, frames, instrument racks, and steering brackets directly impacts operational safety and efficiency.

For these applications, the machining of forks must meet strict technical standards. That includes precise tolerances, durability under heavy loads, and resistance to wear and corrosion. Hengli’s machining services are designed to deliver just that—without compromise.

3. What Makes Hengli’s Fork Machining Services Stand Out?

a. Full-Process Integration

Hengli offers a one-stop machining solution with capabilities that include laser cutting, flame cutting, CNC machining, bending, welding (including robot welding), powder coating, and galvanizing. This means customers can streamline their supply chain and receive finished fork components from a single trusted partner.

b. Large-Scale Capacity

Hengli’s facilities can produce up to 20,000 sets of forklift frames annually, supporting both mass production and customized orders. This scale ensures faster delivery times and better pricing flexibility for clients around the globe.

c. Expert Engineering Support

From the initial consultation to final inspection, Hengli’s team of over 1,600 professionals—including skilled engineers and technicians—ensures every fork component meets the required dimensions, tolerances, and materials as specified in the client’s drawings.

4. Customized Fork Solutions: Beyond Standard Machining

Every client has different requirements. Some may need a fork optimized for extra-heavy load capacity, while others may prioritize lightweight designs for electric forklifts. Hengli’s custom machining services are designed to accommodate all these needs.

Clients can submit their CAD drawings or design concepts, and Hengli’s engineers will evaluate them and develop a detailed machining plan. From steel selection to final surface treatment, every step is aligned with the client’s goals.

5. Cutting-Edge Equipment for Cutting-Edge Results

Precision machining depends heavily on the quality of equipment. Hengli has invested in advanced CNC systems, automated welding lines, and multi-axis cutting machines to ensure consistency, repeatability, and speed.

These tools enable Hengli to carry out complex tasks such as:

-

High-precision drilling and turning

-

Complex contour milling

-

Clean edge laser cutting

-

Full robotic welding for flawless seams

6. Global Clients, Localized Support

Hengli’s fork machining services aren’t just limited to the Chinese market. With an export footprint spanning North America and Europe, the company has successfully served many well-known international brands in the forklift industry.

Even for overseas customers, Hengli offers on-time service through all processes, from design communication to logistics coordination. This makes working with Hengli just as seamless as working with a local supplier—only more efficient and reliable.

7. Quality Control That Sets the Benchmark

Quality assurance is non-negotiable. Hengli employs strict inspection protocols at every step of the machining process, including:

-

Incoming material checks

-

In-process dimensional inspections

-

Load-bearing tests

-

Final surface finish checks

These measures ensure that every fork component leaving the factory not only meets customer specifications but also performs reliably in real-world applications.

8. Supporting Smart Manufacturing with Fork Machining

Hengli is not just keeping up with global trends—it’s setting them. The company is actively building smart factories and promoting full-chain digitization and automation. Fork machining is just one example of how Hengli applies Industry 4.0 principles to enhance efficiency, transparency, and traceability in manufacturing.

With smart systems in place, clients can benefit from:

-

Faster order tracking

-

Predictive maintenance alerts

-

Digital quality reports

-

Real-time production monitoring

9. Conclusion: Why Hengli Is Your Trusted Fork Machining Partner

As the global demand for high-quality forklift components grows, advanced fork machining services have become essential. Hengli’s combination of experience, scale, customization, and technological innovation positions it as a leader in this field. Whether you are a forklift manufacturer, a heavy equipment OEM, or a global distributor, Hengli’s machining solutions can help you stay ahead of the competition.

Choose Hengli for your fork machining needs—and meet the demands of global manufacturing with confidence.

http://www.hlmetal.net

Hangzhou Hengli Metal Processing Co.,Ltd. -

-

AuthorPosts

- You must be logged in to reply to this topic.